Latest Flooring Trends for Modern Homes

Introduction and Outline

Every step in a home tells a story, and the floor is the narrator. It carries the scrape of chairs after dinner, muffles the sprint of little feet in the hallway, and frames the light that spills across a room at sunrise. Choosing flooring isn’t just about color or cost; it’s about daily comfort, cleaning routines, long-term value, and how materials behave with moisture, heat, and time. Modern options invite you to think holistically: sound, slip resistance, air quality, sustainability, and even how a space feels under bare feet on a winter morning. In short, flooring is a design decision and a performance choice rolled into one, and knowing the landscape makes planning easier and more rewarding.

Here’s the roadmap for what follows—skim it, then dive where you need more detail:

– Materials and styles shaping homes right now, from wide-plank wood looks to matte stone tones.

– Practical performance: scratch resistance, denting, wear layers, and water tolerance under real-life conditions.

– Sustainability and health: low-emission finishes, fast-growing resources, and what to look for in third-party labeling.

– Installation and comfort: underlayments, radiant heat compatibility, and sound control between floors.

– A concluding planning guide: budgets, sample testing, subfloor checks, and smart maintenance that extends lifespan.

Because housing, climate, and lifestyles differ, there’s no single winning material for every room. A basement that occasionally gets damp asks for something different than a sun-baked loft. Pets, wheelchairs, rolling office chairs, and heavy furniture also shift what matters most. To stay practical, this guide blends trend notes with objective criteria—like Janka hardness for wood species, abrasion ratings for laminates, and impact sound considerations for multi-level homes. Where numbers help, you’ll see ranges; where touch and feel matter, you’ll get cues for in-person sampling. Think of this as a field manual: clear, thorough, and ready to help you choose floors that look good on day one and keep performing years later.

The New Landscape of Flooring Materials and Styles

Design trends ebb and flow, but a few steady currents define modern floors: natural textures, calm palettes, and surfaces that perform in busy zones like kitchens and entries. Wide planks and long boards create an airy, continuous look that visually expands rooms. Matte and low-sheen finishes remain popular because they diffuse light and hide small scratches better than high-gloss sheens. Pattern is back, too—from chevron and herringbone layouts in wood looks to subtle geometric prints in resilient sheets and tiles. In stone and tile, soft taupes, warm grays, and desaturated sand tones pair easily with both minimalist and rustic interiors. Meanwhile, water-tolerant rigid-core vinyl and porcelain continue to move confidently into kitchens, mudrooms, and full baths where standing water or splashes are common.

Material choices today cover a spectrum of priorities. Solid and engineered wood bring timeless warmth and can be renewed; engineered formats, in particular, handle seasonal humidity swings better thanks to their layered construction. Resilient options—like rigid-core vinyl (often labeled SPC for stone-composite or WPC for wood-composite cores)—offer strong dent resistance and straightforward maintenance, making them appealing in rentals or households with kids and pets. Laminate continues to deliver realistic textures with advanced printing and registered embossing, while improved edge sealing has expanded its use in moisture-prone areas. Tile remains a reliable classic: porcelain for high performance and ceramic for ample style at approachable prices; large-format rectangles and slim grout lines deliver a seamless look that’s both modern and easy to clean. For those who value comfort and quiet, cork adds spring underfoot and gentle acoustic absorption, while bamboo provides a rapidly renewable option with a clean-lined aesthetic.

Cost and complexity vary notably across categories. Material-only ranges (regional prices will differ) commonly fall around these ballparks: – Resilient vinyl planks and tiles: roughly $2–$5 per sq. ft. for mid-grade selections.

– Laminate: about $2–$4 per sq. ft. for many durable residential options.

– Engineered wood: around $4–$10 per sq. ft., depending on wear-layer thickness and species.

– Solid wood: typically $5–$12 per sq. ft., with exotic or specialty cuts higher.

– Porcelain/ceramic tile: often $3–$10 per sq. ft., plus setting materials.

– Natural stone: $7–$20+ per sq. ft., reflecting quarrying and finishing.

– Cork and bamboo: commonly $3–$8 per sq. ft., grade-dependent.

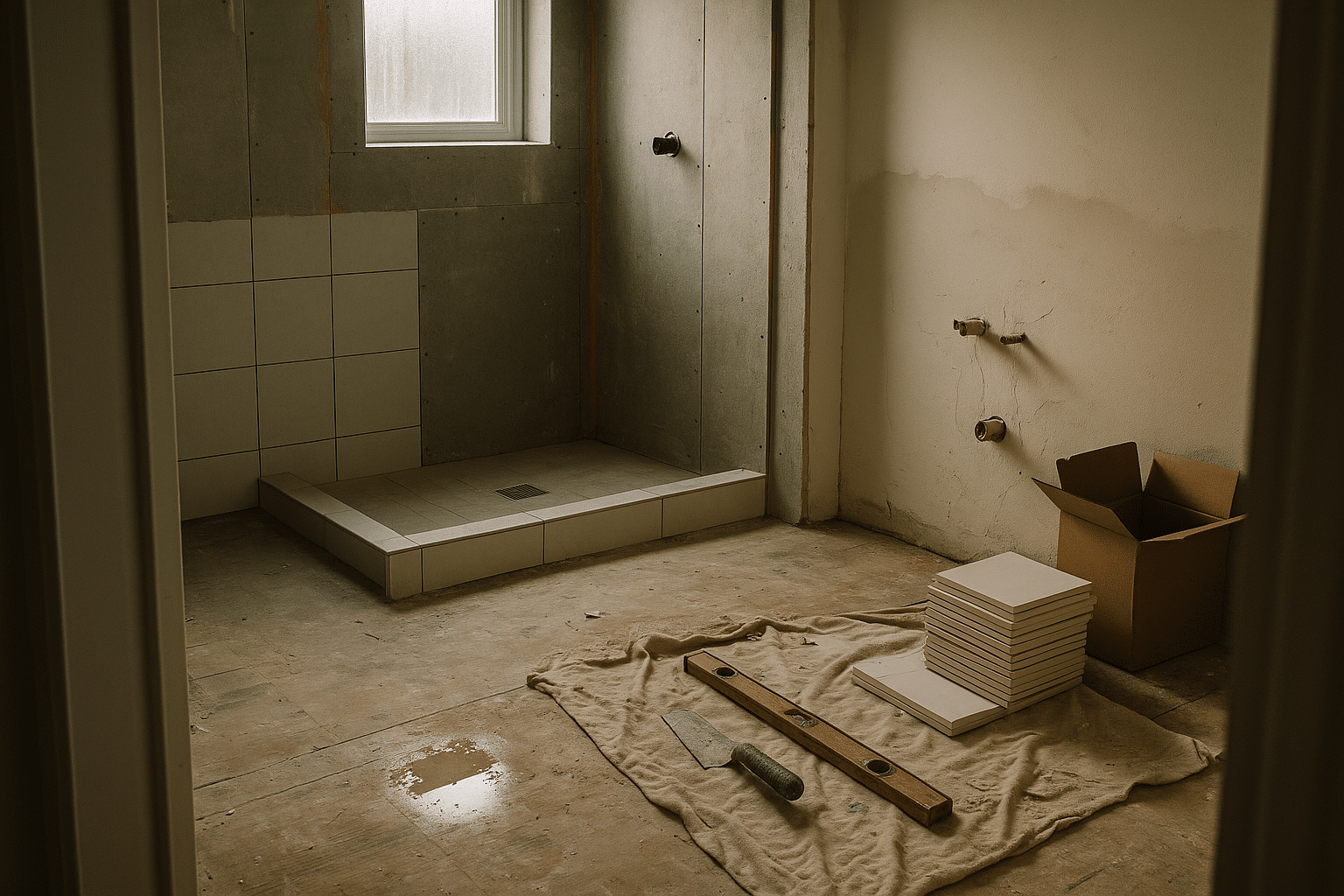

Installation adds labor and materials—underlayments, adhesives, trowels, saw blades, and transitions—so it’s wise to compare installed costs, not materials alone. Layouts with diagonals, borders, or intricate patterns increase time on site. Likewise, subfloor prep (leveling, patching, moisture mitigation) can tilt a quote substantially. If you love a look but worry about practicality in a zone with splashes, consider mixing materials: resilient in an eat-in kitchen, wood or cork in the adjoining family room, and a coordinating tile for the laundry. The unifying theme in modern homes is cohesion across rooms, not necessarily uniformity—variations within a coordinated palette can feel curated and personal.

Performance, Durability, and Real-World Wear

Floors live hard lives. Chairs slide, pets dig in for takeoff, grit sneaks in from outside, and humidity expands and contracts everything made of natural fibers. Understanding how materials wear keeps expectations aligned with reality. Wood hardness is commonly referenced via the Janka scale: many oaks hover around 1,200–1,300, hard maple near 1,450, and strand-woven bamboo can exceed 2,500. Hardness helps with dent resistance but isn’t a shield against scratches; finish chemistry, sheen, and maintenance play big roles. Engineered wood durability depends on wear-layer thickness: a 2–3 mm layer may allow a light rescreen or one sand-and-refinish, while 4–6 mm supports multiple refinishes over decades if the core remains stable.

Laminate flooring is categorized by abrasion ratings; residential products often fall in the AC3–AC4 range, with AC5 for heavier-duty applications. Texture matters: low-sheen, subtly textured surfaces tend to mask micro-scuffs better than glossy, smooth ones. Rigid-core vinyl offers robust dent resistance and good moisture tolerance; check the wear-layer thickness (e.g., 12–20 mil in many homes) and the quality of the urethane finish, which governs stain and scratch resistance. In tile, porcelain’s density makes it durable for busy entries and kitchens; grout choice influences upkeep—narrow joints and stain-resistant grouts reduce cleaning effort. For wet-slip performance on tile, a dynamic coefficient of friction around 0.42 (wet) is commonly cited as a practical threshold in many guidelines; always verify local requirements and product specifications for the intended area.

Acoustics and comfort are equally important. Upstairs spaces benefit from underlayments that boost impact insulation; multifamily buildings often look for IIC and STC ratings in the 50s or higher, depending on local codes and association rules. Thicker, closed-cell underlays can tame footfall noise and add a touch of softness under resilient and laminate planks. Cork naturally cushions and dampens sound, making it pleasant in bedrooms and home offices. Thermal feel varies: tile and stone excel with radiant heat, delivering even warmth and thermal mass; wood and resilient can also pair with radiant systems when installed to manufacturer guidelines and within temperature limits.

Water is the wild card. Kitchens and entries face splashes; bathrooms see daily humidity; basements can harbor vapor from below. Resilient vinyl, porcelain tile, and sealed concrete shrug off moisture, while wood and many laminates require vigilance at seams and spills. In any category, subfloor prep is critical: verify flatness tolerances, test for moisture, and address cracks or deflection before installing. Small choices add up to long-term performance: – Use felt pads under furniture legs and soft casters for rolling chairs.

– Place a walk-off mat inside entries to capture grit and reduce abrasion.

– Clean with neutral pH products recommended for the material and finish.

– Follow climate guidelines; large swings can stress wood and create gaps or cupping.

Sustainability, Indoor Air Quality, and What to Look For

Eco-conscious flooring isn’t a single material but a mindset that weighs source, chemistry, longevity, and end-of-life. Start with resource questions: rapidly renewable materials (such as cork and certain grasses) regrow quickly, while thoughtfully sourced wood supports responsible forestry and can last for generations through refinishing. Stone and ceramic/porcelain are mineral-based and inert; they’re energy-intensive to produce and fire, yet they offer very long service lives. Resilient flooring has evolved with improved wear layers and increasing use of recycled content in some lines; when evaluating, look for transparent disclosures about composition and emissions, and ask for third-party indoor air quality certifications from reputable laboratories rather than relying on marketing claims.

Indoor air quality deserves close attention, especially in tight homes. Finishes, adhesives, and underlayments can emit volatile organic compounds (VOCs) during and shortly after installation. Low-VOC or ultra-low-VOC labels signal stricter limits; independent certifications help confirm that a product’s emissions have been tested against established thresholds. Practical steps help, too: ventilate well during installation, allow adequate cure times, and keep interior temperatures and humidity within manufacturer recommendations. For site-finished wood, waterborne finishes generally have lower odor and faster cure than many solvent-heavy options, though durability varies by formulation and number of coats.

Longevity is often the quietest form of sustainability. A floor that lasts thirty years with light maintenance can outpace a cheaper surface replaced every eight to ten. Refinishing potential matters: thicker engineered wear layers and solid wood can be renewed, while resilient and laminate are typically replaced once the surface is worn. In wet rooms, a truly water-tolerant surface avoids premature tear-outs due to swelling or mold in the substrate. Consider the full cycle: – Production: energy inputs, resource extraction, and transport distances.

– Use phase: cleaning products required, scratch-hiding ability that reduces the urge to replace early, and compatibility with radiant heat to enhance comfort efficiently.

– End-of-life: deconstruction, recyclability, or reuse options such as donating intact planks during remodels.

Comfort and sustainability intersect in daily living. Cork and certain resilient backings add cushioning that can reduce fatigue in kitchens where you stand often. Dense tile over radiant coils creates a gentle, even warmth in winter, while in summer it remains cool to the touch, aiding passive comfort strategies. No single product wins every category, but smart trade-offs—low emissions, durable finishes, and materials suited to each room’s risks—deliver healthy, long-lived floors that feel as good as they look.

Conclusion and Planning Guide for Modern Homes

Turning inspiration into a finished floor is smoother with a clear plan. Begin by mapping your home zone by zone and ranking priorities for each space: water exposure, traffic, pets, noise, and comfort. Kitchens and entries might call for water-tolerant tile or resilient, while bedrooms could emphasize warmth and acoustics through wood, cork, or cushioned planks. Collect large samples and live with them for a few days; watch how they respond to morning sun, evening shadows, and your actual cleaning routine. Put samples by the dishwasher, near the entry mat, and under a chair to see real wear patterns before you commit.

Budget with total cost of ownership in mind, not just the sticker on the box. A simple comparison for a 300 sq. ft. room helps: – Resilient planks at $3.50/sq. ft. materials = $1,050; add underlayment and typical labor, and you might land near $2,000–$3,000 depending on prep.

– Engineered wood at $7.00/sq. ft. materials = $2,100; installed totals could run $3,500–$5,500 when accounting for acclimation and finishing touches.

– Porcelain tile at $5.50/sq. ft. materials = $1,650; because setting, leveling, and grouting are labor-intensive, installed totals may reach $4,000–$6,000 for flat, open layouts.

Regional labor rates and subfloor conditions can swing these numbers; the key is comparing like for like, including trim, transitions, thresholds, and disposal of old flooring.

Before scheduling, check the substrate. Moisture tests in basements and on slabs are non-negotiable for wood and laminate. Confirm flatness tolerances; shallow dips cause hollow spots and clicking, while high ridges can telegraph through rigid products. Ask installers about acclimation windows, expansion gaps, and movement joints in larger tile fields. Discuss warranties, what voids them, and who supplies setting materials and underlayments. A few simple habits extend life significantly: – Keep grit at bay with exterior and interior entry mats.

– Use felt pads and replace them when they compress or peel.

– Clean with manufacturer-recommended products and avoid harsh solvents.

– Address leaks immediately and run exhaust fans to manage humidity.

If you’re outfitting a modern home, the goal is harmony: materials that suit each room’s demands, a palette that flows, and performance that stands up to real life. Wide planks and matte finishes create calm backdrops; resilient and porcelain handle splash zones with poise; wood and cork add warmth where you rest and recharge. Start with your needs, verify the numbers, touch the samples, and choose with confidence. The floor will quietly do its work every day—supporting your routines, softening your steps, and reflecting the life you live, season after season.